Automatic Preset Loading at Oil Depot Loading Racks is a controlled truck-loading solution designed for fuel depots and terminals. Operators preset a target volume or mass on the loading rack (or receive it from the ERP/dispatch system). The system then executes loading automatically through the rack controller/batch controller and metering devices, ensuring each shipment is delivered accurately and consistently.

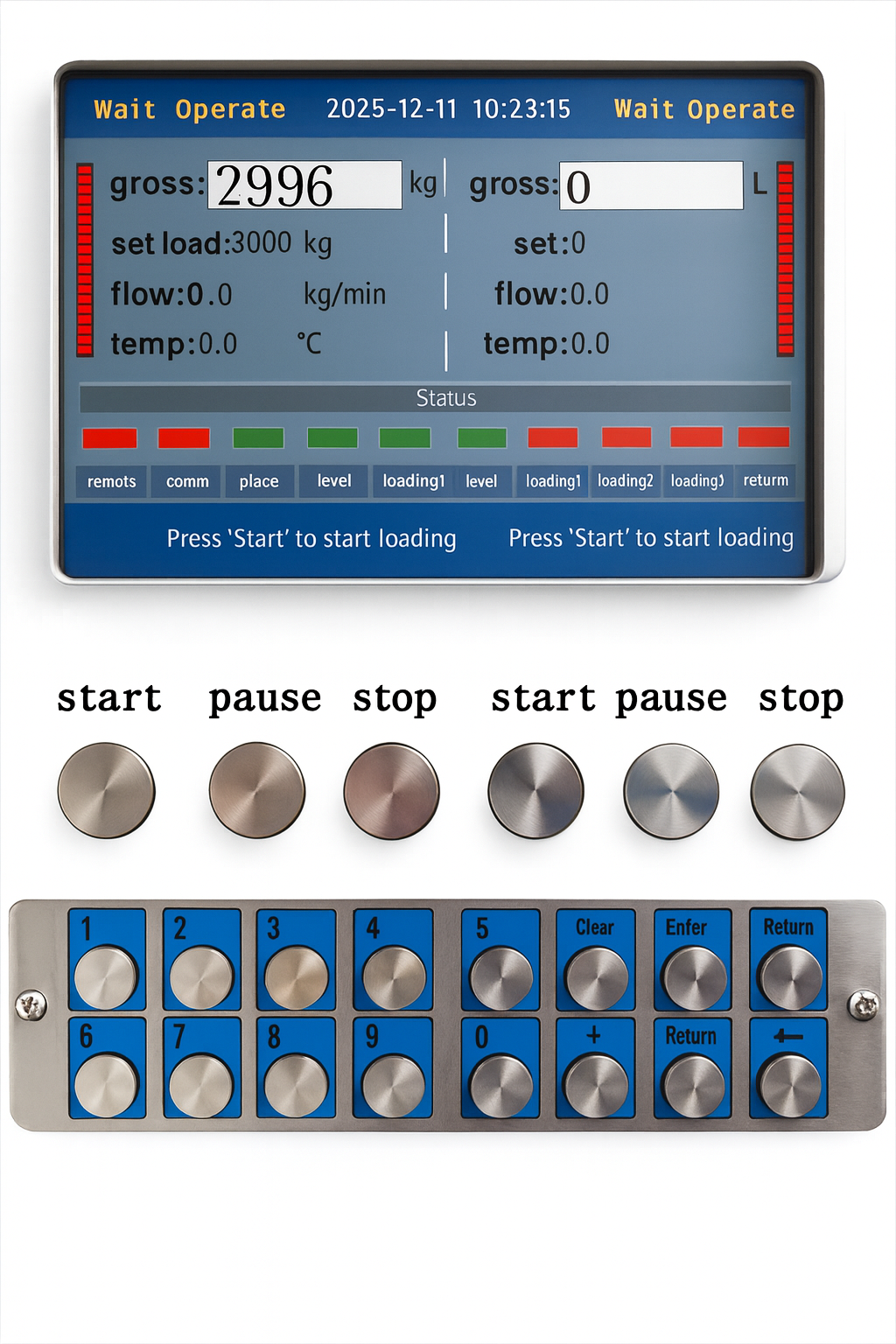

Instruction → Authorization → Loading → Cut-off → Record

A preset loading instruction is issued (from ERP or local rack operation screen)

The driver/vehicle is authorized (optional: card/QR/access control)

Loading starts and the system monitors real-time flow/measurement

The system automatically stops at the preset target and handles safe cut-off

Loading results are recorded and documents can be generated automatically

High accuracy & repeatability: preset control reduces under/over-loading

Faster truck turnaround: standardized steps, fewer manual actions

Loss and dispute reduction: clear measurement records and traceable evidence

Safer operations: supports interlocks and exception handling (site-specific)

Audit-ready data: complete logs by order, truck, bay, operator, and time

Loading rack controller / batch controller

Flow meters / metering skids (temperature/density compensation as required)

Weighbridge systems (if used)

Tank gauging, access control, SCADA/PLC/DCS (site-specific)

Result: a reliable, depot-grade loading process that improves efficiency, compliance, and operational control.

Prev:No Information

Next:No Information